Differences between Joist and Truss

Contents

Joist vs. Truss[edit]

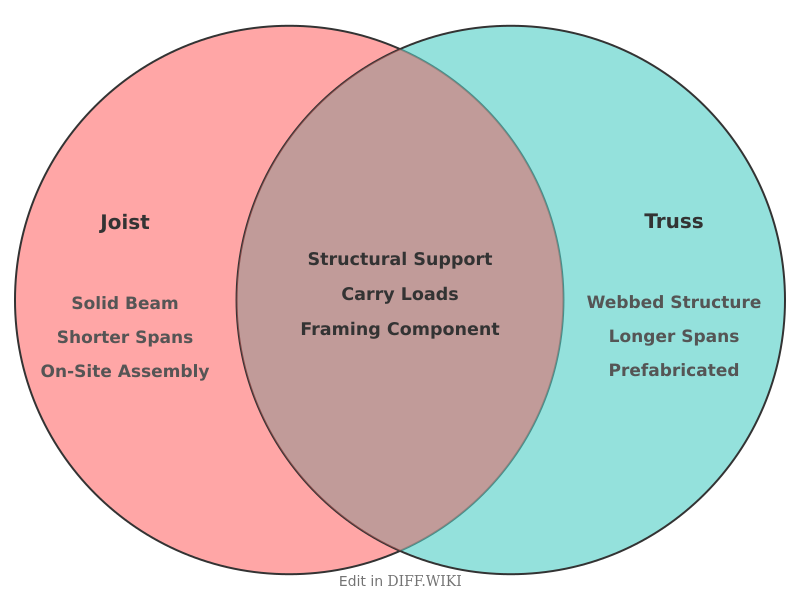

Joists and trusses are structural components used in construction to support floors, ceilings, and roofs.[1] While both serve a similar purpose in providing stability and distributing weight, they differ significantly in their design, application, and installation. A joist is a single horizontal beam, whereas a truss is a prefabricated structure composed of multiple members arranged in a triangular pattern.[2][3]

The choice between using joists or trusses depends on various factors, including the required span, design complexity, budget, and construction timeline.[4] Joists are often used in traditional construction for shorter spans, while trusses are better suited for longer spans and more complex designs.[5][4]

Comparison Table[edit]

| Category | Joist | Truss |

|---|---|---|

| Basic Form | A single horizontal beam made of solid or engineered wood, or steel. | A prefabricated framework of interconnected members forming triangular units. |

| Load Distribution | Distributes loads along its length to supporting walls or beams.[5] | Distributes loads throughout its triangular structure to transfer weight to bearing points.[1] |

| Span Capability | Best suited for shorter spans, typically found in residential construction. | Capable of spanning long distances without intermediate support, ideal for open-concept designs. |

| Installation | Installed on-site, piece by piece, which can be more labor-intensive.[4] | Prefabricated off-site and delivered for faster on-site installation. |

| Cost | Generally lower in upfront material cost, making them suitable for smaller projects. | Higher upfront cost due to engineering and prefabrication, but can reduce labor costs. |

| Design Flexibility | Offers flexibility for on-site adjustments and accommodates simple layouts.[4] | Provides greater flexibility for complex roof designs and architectural styles. |

| Utility Integration | May require drilling for the installation of plumbing, electrical, and HVAC systems.[1] | The open web design simplifies the routing of utilities without the need for cutting. |

Structural Design and Function[edit]

A joist is a horizontal structural member that spans between beams or walls to support floors or ceilings.[5] Joists are typically placed parallel to each other and are commonly made from wood, engineered wood, or steel. Their design is straightforward, focusing on distributing weight evenly across a structure.[5]

A truss, in contrast, is a more complex structural framework of interconnected elements forming a triangular shape.[5] This design allows trusses to distribute loads more efficiently over a wider area, making them suitable for longer spans and larger open spaces without additional support.[5][3] The triangular configuration provides stability and effectively manages both tension and compression forces.

Applications[edit]

Joists are frequently used in both floor and ceiling systems for residential and commercial buildings where the spans are relatively short.[5] Their on-site installation allows for greater customization to fit specific architectural features.[4]

Trusses are ideal for applications requiring long spans, such as in buildings with open floor plans, complex roof designs, or in large structures like bridges.[5][1] Because they are prefabricated, trusses can be installed quickly, which can help to reduce construction time and labor costs.[4] The open design of trusses also allows for easier installation of utilities like plumbing and electrical systems.

Cost and Installation[edit]

The initial material cost for joists is typically lower than for trusses, making them a cost-effective option for smaller projects with shorter spans.[4] However, the on-site installation of joists can be more labor-intensive and time-consuming.

Trusses generally have a higher upfront cost due to the engineering and manufacturing process. However, their prefabricated nature allows for faster installation, which can lead to savings on labor costs. For large projects, the ability of trusses to span greater distances may also reduce the need for additional support structures, potentially offsetting the higher initial material cost.[4]

References[edit]

- ↑ 1.0 1.1 1.2 1.3 "betterlivingcomponents.com". Retrieved December 08, 2025.

- ↑ "ls-usa.com". Retrieved December 08, 2025.

- ↑ 3.0 3.1 "coohom.com". Retrieved December 08, 2025.

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 "buffalorivertruss.com". Retrieved December 08, 2025.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 "rangertruss.com". Retrieved December 08, 2025.