Differences between OSB and Plywood

Contents

OSB vs. Plywood[edit]

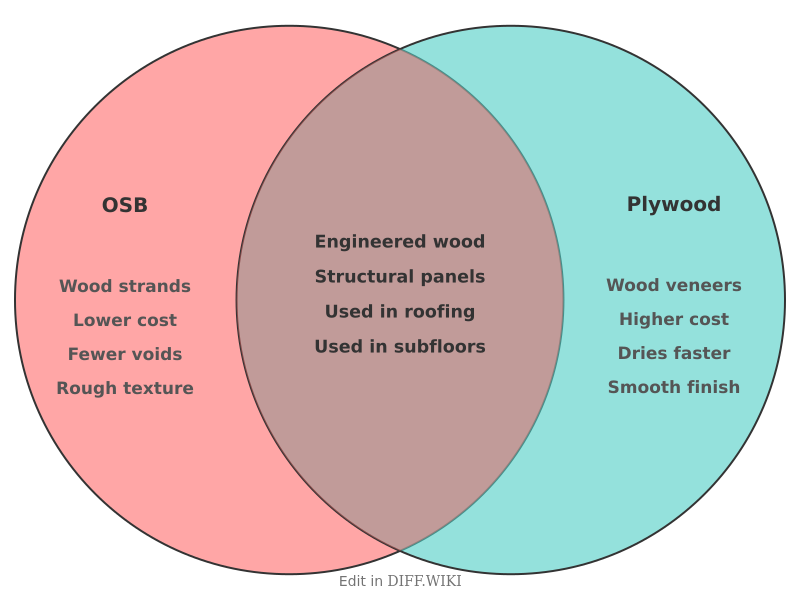

Oriented strand board (OSB) and plywood are both engineered wood panels commonly used in construction for applications like sheathing, subflooring, and roof decking.[1][2] While building codes often recognize them as structurally equivalent, their distinct manufacturing processes result in different characteristics.[3][4] Plywood is made from thin layers of wood veneer, called plies, which are glued together with adjacent layers having their grain rotated up to 90 degrees to one another.[5][2] OSB is produced from rectangular-shaped wood strands arranged in cross-oriented layers, mixed with resins, and hot-pressed into panels.[5][2]

Comparison Table[edit]

| Category | OSB (Oriented Strand Board) | Plywood |

|---|---|---|

| Composition | Wood strands and flakes bonded with adhesive resins under heat and pressure.[3] | Thin sheets of wood veneer (plies) laminated together in alternating grain directions.[5][1] |

| Moisture Resistance | More prone to swelling at the edges when wet and dries more slowly. Swollen areas may not return to their original dimensions. | Generally more resistant to moisture, dries faster, and is less prone to swelling. It is more likely to return to its original shape after getting wet.[5] |

| Strength & Stiffness | Has high shear strength.[3] It is generally more flexible than plywood. | Considered stiffer and has a better strength-to-weight ratio. It performs well under impact and dynamic loads. |

| Cost | Typically 15-30% less expensive than plywood, making it a budget-friendly option for large projects. | Generally more expensive due to its manufacturing process and the need for larger logs.[2] |

| Weight | Heavier than plywood of the same thickness.[5] | Lighter than OSB, which can make it easier to handle during construction.[5] |

| Environmental Impact | Considered more environmentally friendly as it can be made from smaller, fast-growing trees and manufacturing involves less waste. | Traditionally requires larger, slower-growing trees. However, many manufacturers now use sustainable forestry practices. |

| Fastener Holding | Has a weaker grip on nails and screws compared to plywood.[5] | Holds fasteners like nails and screws more securely due to its layered veneer construction.[5] |

Common Applications[edit]

Both materials are used for similar structural applications, including roof decking, wall sheathing, and subflooring. Plywood is often preferred for projects where a smoother finish is desired, such as in cabinetry and furniture, due to its less rough appearance. OSB's lower cost makes it a common choice for sheathing and subfloors where appearance is not a primary concern. For subfloors that will be covered with tile or hardwood, plywood's stiffness is often considered an advantage.

Performance Considerations[edit]

One of the most notable differences is how each material reacts to moisture. Plywood tends to swell less and dry faster than OSB.[5] When OSB gets wet, its edges are prone to significant swelling that may be permanent, which can create uneven surfaces. In terms of strength, both are rated similarly for many structural uses, though plywood is generally stiffer.[4] This added stiffness can be beneficial in flooring, reducing flex between joists. OSB, on the other hand, can be manufactured in larger, more uniform panels without the soft spots that can sometimes be found in plywood veneers.[5][3]

References[edit]

- ↑ 1.0 1.1 "quora.com". Retrieved December 16, 2025.

- ↑ 2.0 2.1 2.2 2.3 "silvaris.com". Retrieved December 16, 2025.

- ↑ 3.0 3.1 3.2 3.3 "alpinestructures.net". Retrieved December 16, 2025.

- ↑ 4.0 4.1 "plyboost.com". Retrieved December 16, 2025.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 "vinawoodltd.com". Retrieved December 16, 2025.