Differences between Scada and Telemetry

SCADA vs. Telemetry

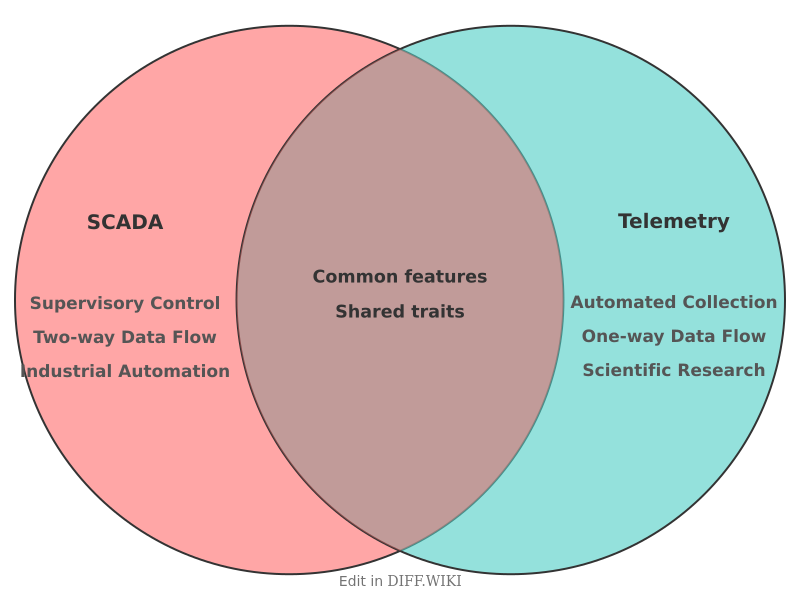

Supervisory Control and Data Acquisition (SCADA) and telemetry are two concepts related to the remote monitoring and control of processes. While they are often used together and share similarities, they have distinct functions and applications. Telemetry is the automated process of collecting measurements and other data from remote sources and transmitting them to receiving equipment for monitoring.[1][2] SCADA is a broader system architecture that includes computers, data communications, and graphical user interfaces to provide high-level supervision and control of machines and processes. In many cases, telemetry is a component of a larger SCADA system.[3]

SCADA systems are a type of industrial control system used to manage and monitor physical processes across various industries, such as electricity transmission, oil and gas pipelines, and water distribution.[4] These systems allow operators to interact with devices like sensors, pumps, and motors through a Human-Machine Interface (HMI).[5] The core of a SCADA system is its ability to perform supervisory operations over a variety of other proprietary devices.

Telemetry, on the other hand, focuses on the automated collection and transmission of data from remote or inaccessible points.[1] The term is derived from the Greek roots 'tele', meaning 'remote', and 'metron', meaning 'measure'.[1] It can utilize various communication methods, including wireless, wired, and optical links.[1][3] Telemetry is widely used in scientific research for applications like monitoring seismographs, weather stations, and wildlife tracking.[1]

Comparison Table

| Category | SCADA | Telemetry |

|---|---|---|

| Primary Function | Supervisory control and data acquisition of industrial processes.[5] | Automated collection and transmission of data from remote sources.[1] |

| Data Flow | Typically two-way, allowing for both monitoring and control commands. | Primarily one-way, from the remote source to a central location for monitoring. |

| Scope | A comprehensive system architecture that includes hardware and software for process management.[4] | A technology focused on the transmission of data over a distance. |

| Components | Includes supervisory computers, RTUs/PLCs, communication infrastructure, and HMI software. | Consists of sensors, a transmission path, and a display or recording device.[3] |

| Typical Applications | Industrial automation, manufacturing, energy grids, water treatment plants.[5] | Scientific research, aerospace, environmental monitoring, fleet management.[1] |

Architecture and Operation

A typical SCADA architecture includes a central master station, or Master Terminal Unit (MTU), which communicates with remote field devices such as Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs). These field devices interface directly with the sensors and actuators of the process being controlled.[5] The HMI presents the collected data to a human operator, who can then issue commands to control the process.

Telemetry systems are generally simpler in their architecture. They consist of a sensor to collect data, a transmission medium to send the data, and a device to receive and display or record the data.[3] While SCADA systems often incorporate telemetry for data transmission, telemetry can also exist as a standalone system purely for monitoring purposes. The communication aspect of a SCADA system's remote management and monitoring is often referred to as telemetry.[3]

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 "wikipedia.org". Retrieved January 02, 2026.

- ↑ "logicmonitor.com". Retrieved January 02, 2026.

- ↑ 3.0 3.1 3.2 3.3 3.4 "wikipedia.org". Retrieved January 02, 2026.

- ↑ 4.0 4.1 "patsaind.com". Retrieved January 02, 2026.

- ↑ 5.0 5.1 5.2 5.3 "aveva.com". Retrieved January 02, 2026.