Differences between Cellulose Insulation and Fiberglass Insulation

Contents

Cellulose insulation vs. fiberglass insulation[edit]

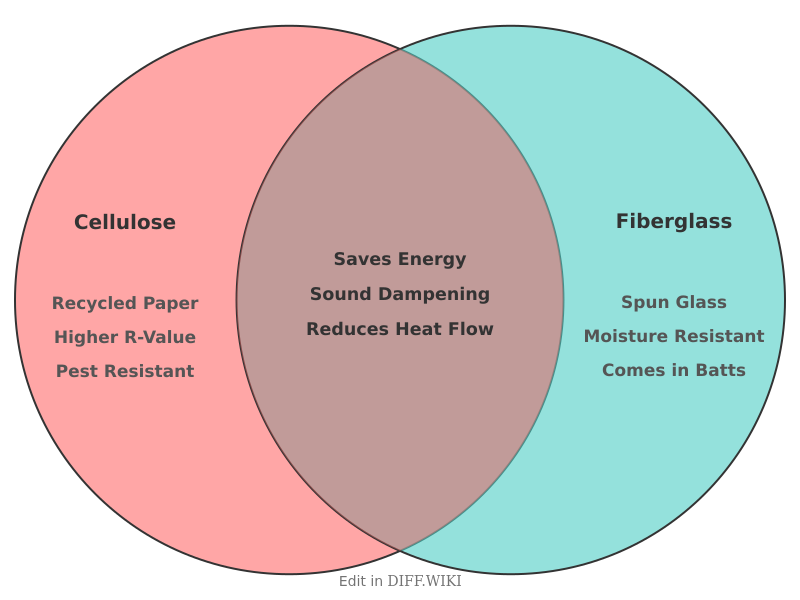

Cellulose and fiberglass are two common types of insulation used in residential and commercial buildings to reduce heat transfer.[1] Fiberglass, made from spun glass fibers, has been a standard insulation material for decades and is available in batts, rolls, and loose-fill form.[1][2] Cellulose insulation is composed primarily of recycled paper products, treated with fire retardants, and is typically installed as a loose-fill material.[1][3]

While both materials serve the same primary function, they differ in thermal performance, material composition, and installation methods.[1][4]

Comparison Table[edit]

| Category | Cellulose | Fiberglass |

|---|---|---|

| Material Composition | Made from up to 85% recycled paper products, treated with borate fire retardants.[5][1][3] | Made from sand and up to 50% recycled glass.[5][4] |

| R-value per inch | 3.2 to 3.8[4] | 2.2 to 2.7[4] |

| Installation | Typically installed as blown-in loose-fill by professionals.[5] | Available as blown-in loose-fill or in batts and rolls suitable for professional or DIY installation.[5] |

| Fire Resistance | Treated with fire retardants to achieve a Class A/1 fire rating.[5] The dense structure limits oxygen, and the material forms a protective char layer when exposed to flames.[1] | Naturally non-combustible and has a Class A/1 fire rating.[5][1] However, some paper facings on batts may be combustible.[1] |

| Sound Dampening | Dense composition provides effective sound reduction.[5] | Provides some soundproofing but is generally less effective than cellulose due to lower density.[5] |

| Moisture Resistance | Can absorb and release moisture. Prone to clumping and moisture absorption if directly exposed to water. | Does not absorb moisture but can lose effectiveness if it becomes wet and compressed. |

| Cost (Material) | Blown-in material is comparable in price to blown-in fiberglass. | Batt and roll forms are generally less expensive than blown-in options. |

| Durability | Lifespan of 20 to 30 years; may settle over time, which can reduce its R-value.[5] | Can last 50 to 100 years and is less prone to settling than cellulose.[5] |

Health and safety[edit]

During installation, fiberglass fibers can be an irritant to the skin, eyes, and respiratory system, and the use of protective gear is recommended.[5] Once installed and enclosed behind walls, it is considered safe.[5] In 2001, the International Agency for Research on Cancer (IARC) reclassified glass wool, a form of fiberglass, as "not classifiable as to its carcinogenicity to humans."

Cellulose insulation is generally considered non-toxic.[5] It is treated with borates, which can cause irritation if absorbed through broken skin or ingested. The installation process can create dust, which may be an irritant for individuals with respiratory sensitivities.

References[edit]

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 "nuwool.com". Retrieved February 09, 2026.

- ↑ "knaufnorthamerica.com". Retrieved February 09, 2026.

- ↑ 3.0 3.1 "attic-bros.com". Retrieved February 09, 2026.

- ↑ 4.0 4.1 4.2 4.3 "pvhvac.com". Retrieved February 09, 2026.

- ↑ 5.00 5.01 5.02 5.03 5.04 5.05 5.06 5.07 5.08 5.09 5.10 5.11 5.12 "buildlabs.com". Retrieved February 09, 2026.