Differences between Fiberglass Insulation and Spray Foam Insulation

Contents

Fiberglass Insulation vs. Spray Foam Insulation

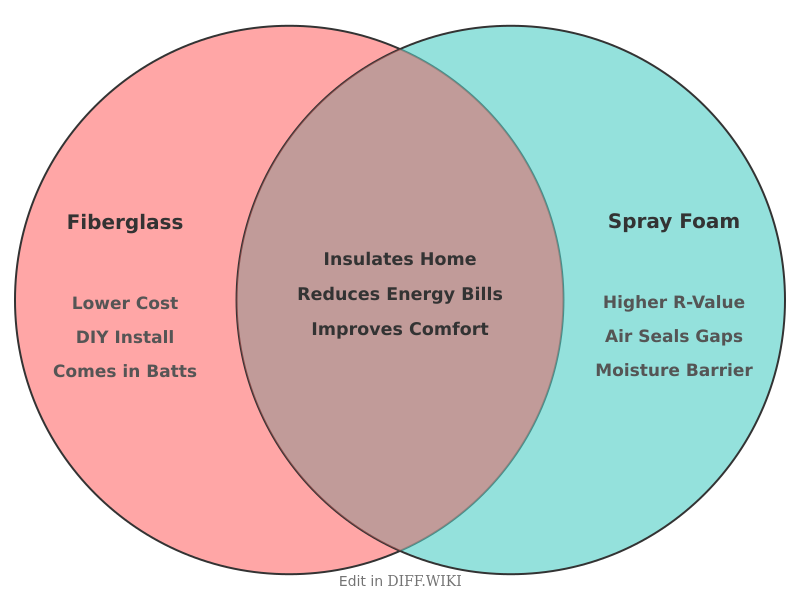

Fiberglass and spray foam are two common materials used for insulating buildings.[1] Fiberglass insulation is composed of fine strands of glass woven together, while spray foam insulation is a liquid-applied material created from the chemical reaction of two components, typically isocyanate and a polyol resin.[2][3][4] Both materials serve to reduce heat transfer, but they differ significantly in their application, performance characteristics, and cost.[5]

Comparison Table

| Category | Fiberglass Insulation | Spray Foam Insulation |

|---|---|---|

| Material Composition | Fine glass fibers, often from recycled glass, sand, and other raw materials. | Polyurethane foam, created by mixing isocyanate and a polyol resin. |

| R-value per Inch | Approximately R-2.2 to R-4.3. | Open-cell: ~R-3.5 to R-4.0; Closed-cell: ~R-6.0 to R-7.0. |

| Air Sealing | Does not create an air barrier on its own; separate air sealing measures are needed to prevent drafts. | Expands upon application to fill gaps and cracks, creating an effective air barrier that reduces air leakage.[1] |

| Moisture Resistance | Can absorb moisture, which may reduce its effectiveness and can lead to mold if it gets wet. | Closed-cell spray foam is moisture-resistant and acts as a vapor barrier.[2] |

| Installation | Can be installed by professionals or as a DIY project, typically in the form of batts, rolls, or loose-fill. | Requires specialized equipment and professional installation due to the chemical mixing process. |

| Lifespan | Can last for several decades but may need replacement every 15 to 30 years as it can settle or be compromised by moisture. | Can last for 80 years or more, as it does not sag or settle over time.[1] |

| Upfront Cost | Generally lower; more cost-effective for initial installation. | Higher initial cost due to materials and the need for professional installation. |

Thermal Performance

The effectiveness of an insulation material is measured by its R-value, which indicates its resistance to heat flow. Spray foam insulation generally has a higher R-value per inch than fiberglass. Closed-cell spray foam offers the highest thermal resistance, with R-values typically ranging from 6.0 to 7.0 per inch. Open-cell spray foam has a lower R-value, around 3.5 per inch.[3] In comparison, the R-value of fiberglass insulation is lower, generally between 2.2 and 4.3 per inch. Furthermore, the R-value of spray foam remains stable over its lifetime, whereas fiberglass can lose some of its insulating capability over time.

Air and Moisture Control

A significant difference between the two materials is their ability to control air leakage. Spray foam insulation expands after being sprayed, which allows it to seal cracks and crevices, creating an airtight barrier. This air sealing capability helps to reduce energy loss from air infiltration. Fiberglass insulation, on the other hand, does not stop airflow on its own and requires additional air-sealing measures to be fully effective.

In terms of moisture, closed-cell spray foam is resistant to water and can act as a vapor barrier, which helps to prevent mold and mildew growth.[2] Fiberglass insulation is susceptible to moisture absorption. If fiberglass becomes wet, its insulating properties are diminished, and it can become a medium for mold growth if not dried properly.

References

- ↑ 1.0 1.1 1.2 "langesprayfoam.com". Retrieved January 15, 2026.

- ↑ 2.0 2.1 2.2 "advancedseal.net". Retrieved January 15, 2026.

- ↑ 3.0 3.1 "paragon-protection.com". Retrieved January 15, 2026.

- ↑ "scsfoam.com". Retrieved January 15, 2026.

- ↑ "gni.ca". Retrieved January 15, 2026.