Differences between MDF and Plywood

Contents

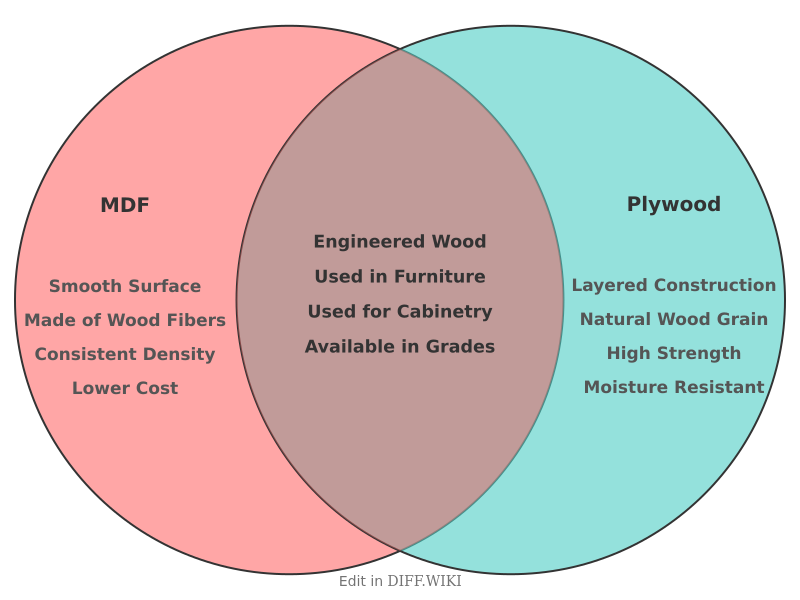

MDF vs. Plywood

Medium-density fiberboard (MDF) and plywood are both engineered wood products widely used in construction and furniture making.[1] While they can be used for similar applications, their distinct manufacturing processes and materials result in different characteristics.[1][2] MDF is created by breaking down hardwood or softwood residuals into fine wood fibers, which are then combined with wax and a resin binder and pressed into panels under high temperature and pressure.[3][4] Plywood is constructed from thin layers of wood veneer, called plies, that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.[5]

Comparison Table

| Category | MDF | Plywood |

|---|---|---|

| Composition | Wood fibers, wax, and resin binder | Thin layers (plies) of wood veneer bonded with adhesive |

| Surface Appearance | Smooth, uniform surface with no wood grain | Natural wood grain pattern is visible |

| Strength | Consistent density but less strong and not suitable for heavy loads | Stronger due to cross-grain construction, suitable for structural use |

| Moisture Resistance | Prone to swelling and damage from moisture unless specially treated | Generally more resistant to moisture, with marine-grade options available |

| Workability | Easy to cut and shape into detailed designs without splintering | Can splinter during cutting, making detailed designs more difficult |

| Cost | Typically more affordable than plywood | Generally more expensive, with prices varying by grade and wood type |

| Weight | Denser and heavier than plywood | Lighter in weight compared to MDF |

Properties and Characteristics

The primary difference in the construction of MDF and plywood leads to significant variations in their properties. Plywood's cross-laminated structure gives it superior structural strength and durability compared to MDF, making it a better choice for load-bearing applications such as subfloors and roofing.[5] MDF, while not as structurally strong, has a very smooth and consistent surface, which makes it an ideal substrate for painting, veneering, or applying laminates.

In terms of moisture resistance, standard MDF performs poorly, readily absorbing water which causes it to swell and deteriorate. While moisture-resistant varieties of MDF are available, plywood generally offers better resistance to humidity and moisture, and specific types like marine-grade plywood are designed for wet environments. MDF is heavier and denser than plywood. This density contributes to its smooth finish but also makes it more difficult to handle. Plywood is lighter and its layered structure holds screws more securely than MDF's fine particle composition.

Common Applications

The choice between MDF and plywood often depends on the specific requirements of the project. MDF's smooth surface and ease of machining make it a popular choice for indoor applications like cabinetry, shelving, interior trim, and decorative panels.[3] It is particularly well-suited for projects that will be painted, as it provides a flawless finish without a grain pattern showing through.

Plywood is favored for applications where strength, durability, and moisture resistance are key. This includes structural elements in construction, such as wall sheathing, flooring, and roof decking. It is also commonly used for furniture that needs to bear weight, such as bed frames and tables, as well as in kitchens and bathrooms where humidity is a concern.[2]

References

- ↑ 1.0 1.1 "thespruce.com". Retrieved December 11, 2025.

- ↑ 2.0 2.1 "greenply.com". Retrieved December 11, 2025.

- ↑ 3.0 3.1 "wikipedia.org". Retrieved December 11, 2025.

- ↑ "onsungroup.com". Retrieved December 11, 2025.

- ↑ 5.0 5.1 "wikipedia.org". Retrieved December 11, 2025.