Differences between Hammer Drill and Rotary Hammer

From diff.wiki

Hammer Drill vs. Rotary Hammer[edit]

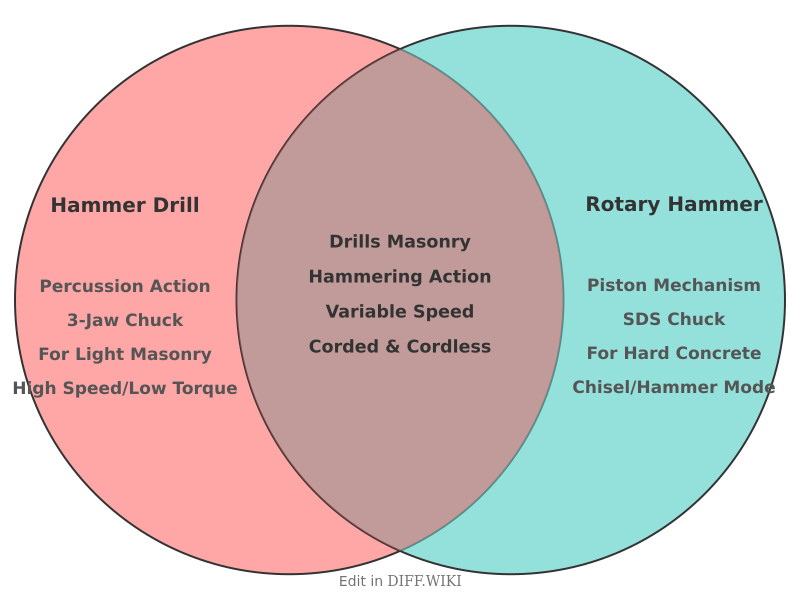

A hammer drill and a rotary hammer are tools that both combine a rotational drilling action with a hammering impact to bore through hard materials such as masonry and concrete.[1] While they serve similar functions, they utilize different mechanisms to generate force, which makes them suitable for different applications.[2][3] A hammer drill is generally used for lighter-duty tasks, while a rotary hammer is better suited for more demanding jobs.[4]

Comparison Table[edit]

| Category | Hammer Drill | Rotary Hammer |

|---|---|---|

| Mechanism | Employs two ridged, spinning discs that click in and out against each other, creating a high-speed vibrating or chattering action.[1][3] This percussive force is less powerful and often relies on user-applied pressure.[5] | Uses an electro-pneumatic piston mechanism driven by a crankshaft to create a powerful, hammering blow.[1] This system generates significantly more impact energy.[2][1] |

| Primary Application | Suited for drilling smaller diameter holes (typically up to 1/2 inch) in lighter masonry like brick, mortar, and concrete block.[5] It can also function as a standard drill for wood or metal by disabling the hammer mode. | Designed for heavy-duty drilling of larger holes (over 1/2 inch) in dense materials such as poured concrete and stone.[5] Many models offer a "hammer-only" mode for light demolition and chiseling tasks.[1][3] |

| Power and Impact Force | Power is measured in Blows Per Minute (BPM), with a less forceful impact. It is effective for occasional use in softer masonry.[5] | Impact energy is measured in foot-pounds (ft-lbs), indicating a much stronger and more efficient impact. This allows for faster drilling in hard materials with less user effort.[1] |

| Size and Weight | Generally smaller, lighter, and more compact, making them easier to handle, especially in tight spaces or for overhead work.[2] | Larger and heavier due to the more complex internal mechanism and powerful motor, which can cause user fatigue during prolonged use.[2] |

| Chuck Type | Typically uses a standard three-jaw chuck that holds round-shank bits, which are tightened with a key or by hand. | Uses an SDS (Slotted Drive System) chuck (e.g., SDS-Plus or SDS-Max), which allows specialized bits to lock in securely and move independently for better impact transfer.[5][1] |

| Durability | The mechanism can experience significant wear and tear under heavy, prolonged use, especially when drilling into very hard materials.[1] | Built for professional and frequent use, the piston mechanism is more durable and can withstand the demands of heavy-duty applications.[1] |

| Cost | More affordable, making them a common choice for homeowners and for occasional light masonry work.[5] | Generally more expensive, reflecting their greater power, durability, and more complex design. They are a common tool for construction professionals.[5][1] |

References[edit]

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 "familyhandyman.com". Retrieved December 20, 2025.

- ↑ 2.0 2.1 2.2 2.3 "toolsmyne.com". Retrieved December 20, 2025.

- ↑ 3.0 3.1 3.2 "factorydirectsupply.com". Retrieved December 20, 2025.

- ↑ "cuttingtoolsinc.com". Retrieved December 20, 2025.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 "midlandtool.com". Retrieved December 20, 2025.