Differences between PVC and uPVC

Contents

PVC vs. uPVC[edit]

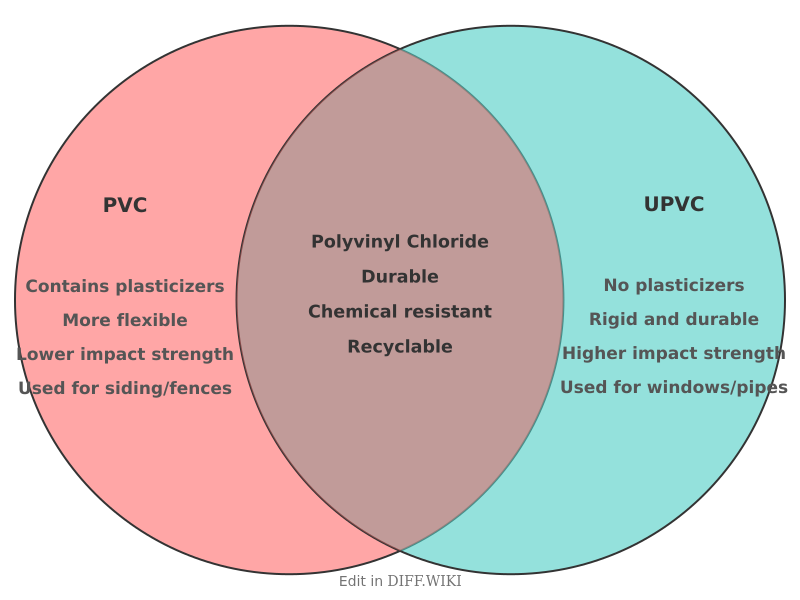

Polyvinyl chloride (PVC) is a versatile thermoplastic polymer produced from vinyl chloride monomers.[1][2] To create the familiar flexible form of PVC, plasticizers are added to the base material.[3][4] Unplasticized polyvinyl chloride (uPVC), also known as rigid PVC, is the same polymer without the addition of these plasticizers.[1][5] This fundamental difference in composition results in distinct physical properties and, therefore, different applications for each material.[2]

Comparison Table[edit]

| Category | PVC | uPVC |

|---|---|---|

| Composition | Contains plasticizers (e.g., phthalates, BPA) to increase flexibility.[3] | Does not contain added plasticizers, resulting in a rigid structure.[1] |

| Flexibility | Soft and flexible, allowing it to be bent and shaped easily. | Rigid and stiff; does not bend easily and maintains its shape. |

| Durability | Less durable than uPVC; can degrade and become brittle with prolonged sun exposure.[4] | Highly durable with strong resistance to weathering, chemicals, and UV radiation, giving it a longer lifespan.[1] |

| Common Uses | Electrical cable insulation, flooring, inflatable products, and flexible tubing.[2] | Window and door frames, plumbing pipes, and exterior cladding.[1][4] |

| Impact Resistance | Lower impact resistance due to its softer composition. | Higher impact resistance, making it suitable for construction applications requiring strength. |

| Maintenance | May require more frequent cleaning and maintenance to prevent discoloration and deterioration. | Low maintenance requirements; can be cleaned with a damp cloth and does not require painting or sealing. |

| Cost | Generally lower initial cost due to lower manufacturing expenses.[1] | Higher initial cost, but can be more cost-effective over the long term due to its durability and low maintenance.[1][3] |

| Recyclability | Difficult to recycle, with some estimates suggesting only 1% is recyclable. | Recyclable and can be reshaped at high temperatures to create new products.[4] |

Durability and Maintenance[edit]

The absence of plasticizers makes uPVC significantly more durable and impact-resistant than flexible PVC. uPVC's rigid structure holds up better against weathering, fluctuations in temperature, and physical stress. For example, uPVC window frames can have a lifespan of up to 35 years and are resistant to fading. In contrast, the plasticizers in PVC can break down over time, especially with exposure to sunlight, leading to a loss of flexibility and increased brittleness.

In terms of maintenance, uPVC has a clear advantage. Its non-porous surface requires minimal upkeep, typically only needing to be wiped down with a damp cloth to retain its appearance. Flexible PVC, however, may require more intensive or frequent cleaning to manage discoloration and prevent material degradation over its lifespan.

Environmental Considerations[edit]

The environmental impact of PVC and uPVC differs primarily due to their composition and recyclability. The production and disposal of PVC can release harmful chemicals, and the plasticizers it contains, such as phthalates and BPA, have raised environmental and health concerns.[1][3] Furthermore, PVC is challenging to recycle.

uPVC is often considered a more sustainable option.[1] It does not contain these controversial plasticizers and is more readily recyclable.[4] The material can be melted down and reformed into new products, which reduces waste and the environmental footprint associated with its lifecycle.[4]

References[edit]

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 "oriplast.com". Retrieved November 21, 2025.

- ↑ 2.0 2.1 2.2 "scottopipes.com". Retrieved November 21, 2025.

- ↑ 3.0 3.1 3.2 3.3 "replacewindowslimited.co.uk". Retrieved November 21, 2025.

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 "realplast.in". Retrieved November 21, 2025.

- ↑ "futurewood.com.au". Retrieved November 21, 2025.