Differences between Quality Assurance and Quality Control

Contents

Quality Assurance vs. Quality Control[edit]

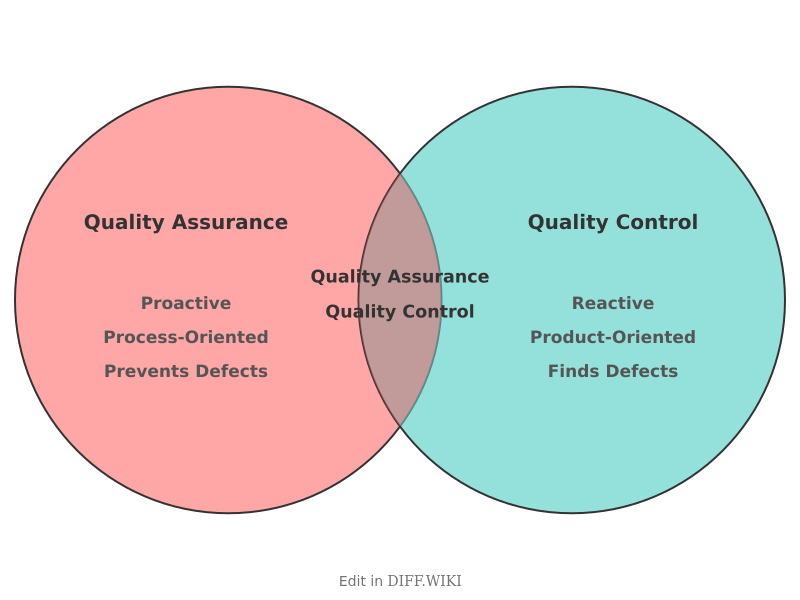

Quality Assurance (QA) and Quality Control (QC) are two components of quality management.[1] Although the terms are often used interchangeably, they represent distinct concepts.[2][3] QA focuses on preventing defects by examining the processes and systems that produce a product or service.[4] QC, in contrast, is focused on identifying defects in the finished product through inspection.[2][5]

According to the International Organization for Standardization (ISO) standard ISO 9000, QA is the "part of quality management focused on providing confidence that quality requirements will be fulfilled." QC is defined as the "part of quality management focused on fulfilling quality requirements." In practice, QA is a proactive, process-oriented approach intended to prevent issues before they occur. QC is a reactive, product-oriented approach designed to detect and correct defects after they have happened.[5]

Comparison Table[edit]

| Category | Quality Assurance (QA) | Quality Control (QC) |

|---|---|---|

| Focus | Process-oriented: Aims to prevent defects by improving development and production processes.[5] | Product-oriented: Aims to identify and correct defects in the final product.[5] |

| Approach | Proactive: Establishes systems and procedures to ensure quality is built into the product lifecycle.[2] | Reactive: Inspects and tests products to find issues after they have occurred.[2] |

| Timing | Occurs throughout the entire product development lifecycle, from concept to launch and beyond.[2] | Takes place at specific points, typically during and after production, before the product reaches the customer.[2] |

| Objective | Defect prevention: To create and implement processes that ensure quality from the start. | Defect detection: To find and resolve errors in the finished product through inspection and testing. |

| Responsibility | Generally involves the entire team, as everyone follows the established processes and standards. | Typically the responsibility of a dedicated team or personnel who conduct inspections and tests. |

| Orientation | System-oriented: Focuses on the overall system of producing a product or service. | Product-oriented: Focuses on the final output to ensure it meets specifications. |

Quality Assurance in Practice[edit]

QA activities are integrated into every stage of the product development lifecycle, from the initial design to post-launch support. The goal is to build quality into the process, rather than checking for it at the end.[5] This involves creating and maintaining a set of procedures, or standard operating procedures (SOPs), that guide the production process.[2]

Common QA methodologies include Statistical Process Control (SPC), which uses statistical methods to monitor and control processes, and Process and Product Quality Assurance (PPQA), which sets organizational standards to address quality issues. Audits are another key function of QA, used to compare the actual processes with the required ones and report the findings to management.[1] The responsibility for QA is often shared by all members of a team, as everyone is expected to adhere to the established quality standards and procedures.

Quality Control in Practice[edit]

QC activities are centered on the inspection and testing of the product to ensure it meets the predefined quality standards.[1] These activities occur at various points in the production process, including inspections of raw materials, in-process checks, and final product testing before it is released to the customer. The primary goal of QC is to identify and correct any defects that were not prevented by the QA processes.[2]

QC is a hands-on activity, often carried out by a specific team of inspectors or testers.[4] Common QC techniques include acceptance sampling, where a subset of a batch is tested, and the use of control charts to monitor process behavior over time. Automated testing may also be used to check for parameters such as size, strength, or functionality, which helps to reduce human error. By identifying and rectifying defects, QC provides feedback that can be used to improve the QA processes over time.