Differences between Scratch Proof and Scratch Resistant

Contents

Scratch Proof vs. Scratch Resistant[edit]

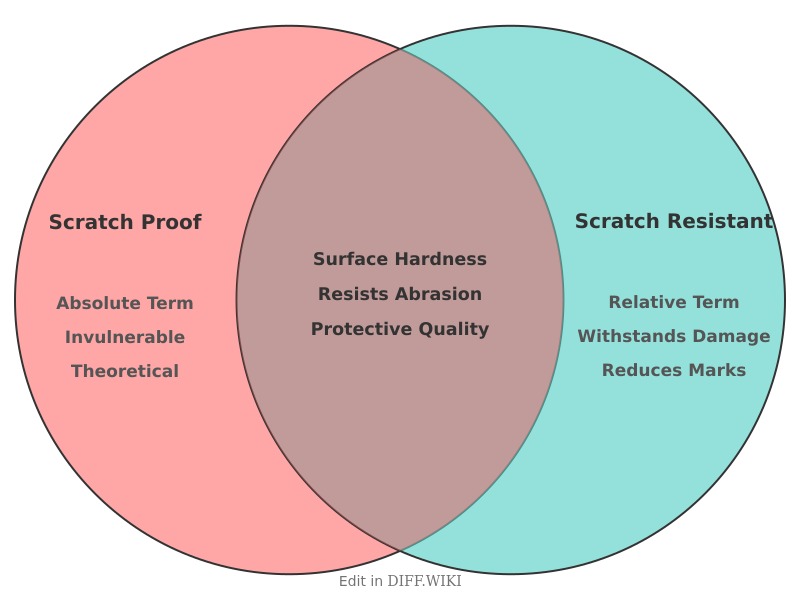

The terms scratch proof and scratch resistant are often used in marketing to describe the durability of a material's surface, particularly for products like watches, electronic screens, and eyewear.[1][2] However, the terms are not synonymous.[2] "Scratch resistant" indicates that a material has the ability to resist damage from minor scratches, while "scratch proof" implies a higher, almost absolute, level of protection against scratching under normal use.[1][2] In practice, no material is completely immune to scratching.[3][4] Therefore, "scratch proof" is often considered a misnomer, with "scratch resistant" being the more accurate technical description for most materials.[4][5]

The ability of a material to resist scratching is related to its surface hardness. Hardness can be measured on various scales, with the Mohs scale being a common method for comparing the scratch resistance of minerals. This scale ranks materials from 1 (softest, like talc) to 10 (hardest, like diamond). A material with a higher Mohs rating can scratch a material with a lower rating. For manufactured products, scratch resistance is often achieved by applying a hard, protective coating or by using inherently hard materials. These coatings are thin, clear layers that bond to the surface, making it more durable against daily wear.

Comparison Table[edit]

| Category | Scratch Proof | Scratch Resistant |

|---|---|---|

| Definition | Implies complete immunity to scratches under normal conditions.[2] | Denotes an ability to withstand or minimize minor scratches and abrasions.[2] |

| Level of Protection | Suggests the highest possible level of durability against abrasion.[4] | Offers a good level of protection against everyday wear and tear, but can still be scratched by harder materials or significant force.[2] |

| Practicality | Considered by many to be a marketing term, as virtually no material is completely immune to all scratches.[3][4][5] | A more accurate and commonly used technical term describing a material's enhanced surface hardness.[4] |

| Method of Achievement | Often refers to materials with very high hardness, such as sapphire (9 on the Mohs scale) used in high-end watch crystals. | Typically achieved by applying a specialized clear coating or by using materials like polycarbonate with enhanced hardness. |

| Common Applications | High-end watch faces, industrial equipment, and specialized optics. | Eyeglass lenses, smartphone screens, automotive paint, and furniture surfaces. |

| Failure Condition | Can still be scratched by materials that are harder, such as diamond, or by a significant impact. | Can be scratched by sharp objects, abrasive materials, or accidental drops.[2] |

Scratch Resistance in Materials[edit]

The scratch resistance of a material is fundamentally tied to its hardness and the strength of its chemical bonds. Materials with strong covalent bonds, like diamond and corundum, are extremely hard and thus very resistant to scratching. In polymers and plastics, scratch resistance can be enhanced by increasing the cross-linking of polymer chains or by adding fillers like glass fibers or nanoparticles to increase surface hardness.

For many consumer products, scratch resistance is imparted through surface coatings. These anti-scratch coatings are thin films, often only nanometers to micrometers thick, that are applied to the surface of a softer material like plastic or glass. Common materials used in these coatings include titanium dioxide, silicon dioxide, and specialized polymers. These coatings not only protect the underlying surface from physical damage but can also improve the product's longevity and appearance by preventing minor blemishes that can accumulate over time. This is particularly important for optical applications like eyeglasses and camera lenses, where even small scratches can impair function.

References[edit]

- ↑ 1.0 1.1 "bregawatches.com". Retrieved December 24, 2025.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 "difference.wiki". Retrieved December 24, 2025.

- ↑ 3.0 3.1 "americasbest.com". Retrieved December 24, 2025.

- ↑ 4.0 4.1 4.2 4.3 4.4 "differencebetween.net". Retrieved December 24, 2025.

- ↑ 5.0 5.1 "bpssoutheast.com". Retrieved December 24, 2025.